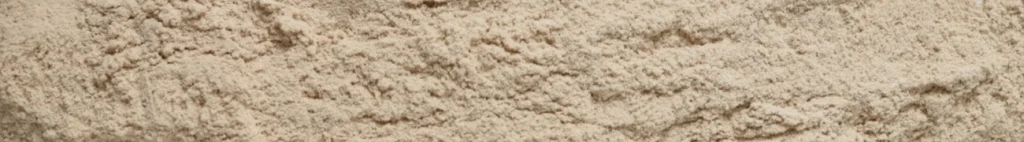

Wood Powder

MANUFACTURING PROCESS

1

Collect and sort materials, removing contaminants and debris.

2

Dry materials to achieve stable, consistent moisture levels.

3

Grind materials through primary milling to reduce overall size.

4

Refine materials using fine grinders to achieve target powder grade.

5

Screen to ensure uniformity and remove oversized particles.

6

Pack finished wood powder and store in clean, dry warehouses.