Maintaining a pristine environment is the cornerstone of any successful dairy or beef operation. A dirty barn is more than just an eyesore; it is a breeding ground for pathogens that can lead to mastitis, hoof rot, and respiratory infections. For farm owners, cleaning cow farm facilities is a non-negotiable task that directly impacts the bottom line.

In this professional guide, we will walk through the essential steps of cattle barn cleaning, explore the best practices to clean cows barn areas, and provide a definitive answer on how to clean a cow shed efficiently.

The Critical Importance of Cleaning Cow Farm Operations

Why is hygiene the primary concern for modern ranchers? The health of the animal is inextricably linked to the cleanliness of its environment. When cows stand in manure or damp bedding, their immune systems are constantly under fire.

Disease Prevention: Regular cleaning cow farm protocols drastically reduce the presence of E. coli and Streptococcus, which are primary causes of environmental mastitis.

Milk Quality: For dairy farmers, a clean environment means cleaner udders and lower somatic cell counts (SCC), leading to higher-quality milk and better premiums.

Hoof Health: Ammonia from urine and moisture from manure soften the hoof, making it susceptible to digital dermatitis. A dry, clean barn is the best defense against lameness.

Step-by-Step: How to Clean a Cow Shed Like a Pro

To maximize efficiency and ensure bio-security, you need a systematic approach. Follow these five steps to master how to clean a cow shed:

Step 1: Animal Relocation and Initial Clearing

Never attempt a deep clean with the animals inside. Move the herd to a secondary paddock or an exercise lot. Begin by removing all portable equipment, such as water troughs (if mobile) and brushes. This provides a clear path for machinery and prevents the contamination of feeding tools.

Step 2: Dry Cleaning and Waste Removal

The first active phase of cattle barn cleaning is the removal of organic matter. Use a skid-steer loader or manual scrapers to remove manure and spent bedding.

Expert Tip: Organic matter neutralizes many disinfectants. If you don’t remove the “visible” dirt first, your chemical cleaners will be ineffective.

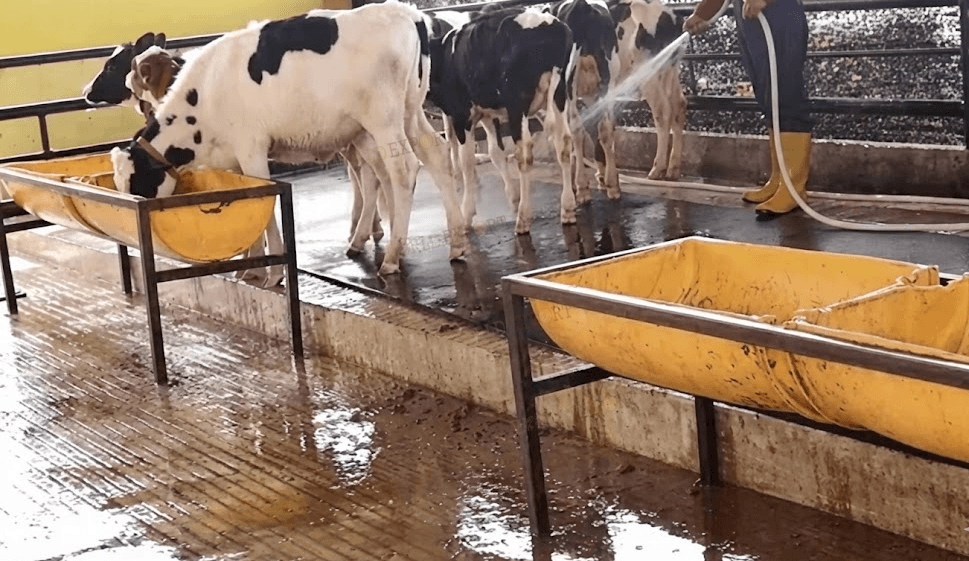

Step 3: High-Pressure Washing

Once the bulk waste is removed, use a high-pressure washer to blast away biofilms and hardened grime from the floors, walls, and stanchions. Pay close attention to the “splash zone”- the lower 4 feet of the walls – where most bacteria reside.

Step 4: Disinfection

Apply a broad-spectrum disinfectant once the surfaces are clean. To clean cows barn areas effectively, ensure the disinfectant has the required contact time (usually 10–20 minutes) before rinsing. Choose a product that is effective against the specific pathogens prevalent in your region.

Step 5: The Drying and Bedding Phase

Bacteria thrive in moisture. After washing, the barn must be allowed to dry completely. Once dry, the final step is to apply a fresh, high-absorbency bedding material. This is where the quality of your supplier becomes vital.

=> Learn more about Newborn Calf Care: A Complete Guide to Raising Healthy Calves

The Role of Premium Bedding in Cattle Barn Cleaning

Effective hygiene doesn’t end when the water is turned off. In fact, what you put back into the barn is just as important as what you took out. To keep the clean cows barn environment stable between deep cleans, you must use bedding that manages moisture and ammonia.

We recommend Wood Sawdust or Mixed Wood Shavings. Unlike traditional straw, which can be dusty and prone to mold, kiln-dried wood products offer:

Superior Absorbency: They pull moisture away from the cow’s skin and hooves.

Ammonia Control: High-quality wood bedding traps odors, improving the air quality for both the livestock and the workers.

Pathogen Resistance: Properly processed wood shavings have a lower bacterial load compared to organic materials like recycled manure solids or straw.

World Export: Your Global Partner in Farm Hygiene

Since 2017, World Export has been a leading Vietnamese company specializing in the export of premium wood products for the global agricultural sector. We understand that in a cleaning cow farm routine, consistency is key.

All our products are sourced from sustainably managed forests and processed in our state-of-the-art factories. Our advanced drying and screening systems ensure that every batch has low moisture content and high absorbency, providing the perfect finishing touch to your cattle barn cleaning protocol.

Our Professional Packaging Standards

To ensure our international clients receive the best value and easy handling, we offer specialized packaging for our wood products:

- Wood Sawdust Packaging

Jumbo Bags: 500 – 600 kg with pallets; 24 tons/40HC; 40 bags/container.

Bag size: 110 x 110 x 120 cm

Pallet size: 100 x 100 x 9 cm

Wood Shavings Packaging

Jumbo Bags: 500 – 600 kg with pallets; 24 tons/40HC; 40 – 48 bags/container. Bag Size: 110x110x120.

Plastic Bags (Bulk): 20 kg bags; 1,200 – 1,300 bags; ~ 20 tons/40HC.

Plastic Bags (Pallet): 20 kg bags; wrapped by PE; 40 pallets; 960 bags/container.

Conclusion: A Clean Barn is a Profitable Barn

Mastering how to clean a cow shed is an investment in your farm’s future. By following a rigorous cleaning cow farm schedule and utilizing high-quality, sustainable bedding materials from World Export, you create an environment where your cattle can reach their full genetic potential.

A clean barn means healthier cows, higher yields, and a more sustainable farming operation. Don’t let poor hygiene hold your business back.

Ready to optimize your barn hygiene? Contact World Export today to discuss how our high-absorbency wood shavings and sawdust can revolutionize your farm management.